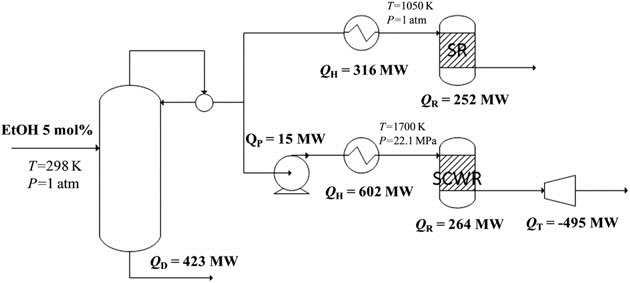

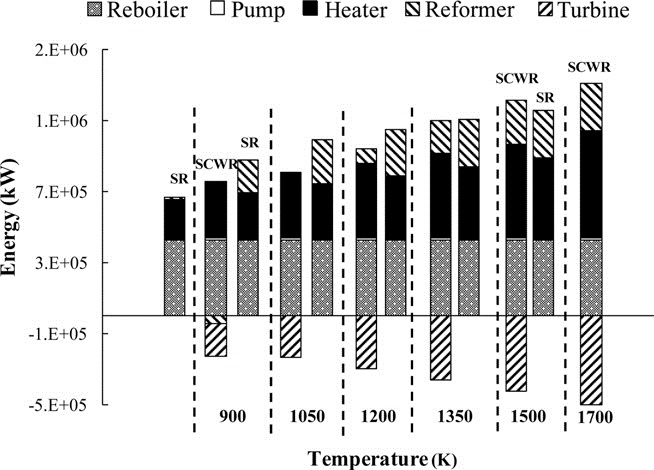

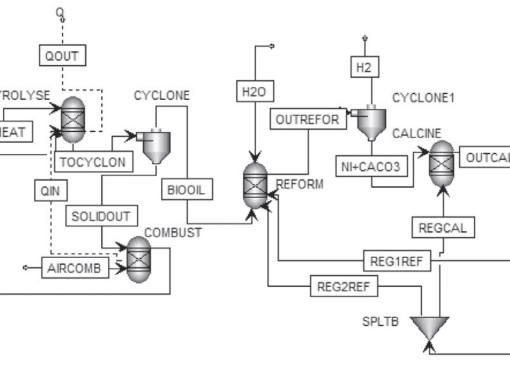

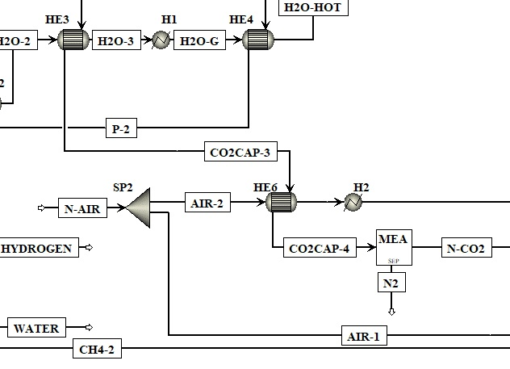

Theoretical study of fuel gas (H2 & CO) production for SOFC from bioethanol was carried out to compare performances between two reforming technologies, including steam reforming (SR) and supercritical-water reforming (SCWR). It demonstrates that the fuel gas productions are comparable among the two reforming systems; however, SCWR requires the operation at much higher temperature and pressure than SR. The maximum hydrogen yield can be obtained at 850 K, atmospheric pressure, ethanol to water molar feed ratio of 1:20 for SR system and at 1300 K, 22.1 MPa, and ethanol to water feed ratio of 1:20 for SCWR. The use of a distillation column to purify the bioethanol feed was proven to improve the fuel conversion efficiency of both systems. The analysis reveals that SCWR is a promising system for fuel production for SOFC when a gas turbine is incorporated to the system for energy recovery. Further, it is not necessary to distil bioethanol to obtain too high ethanol recovery (i.e. > 90%) as higher energy consumption at the distillation column could lead to lower overall thermal efficiency.