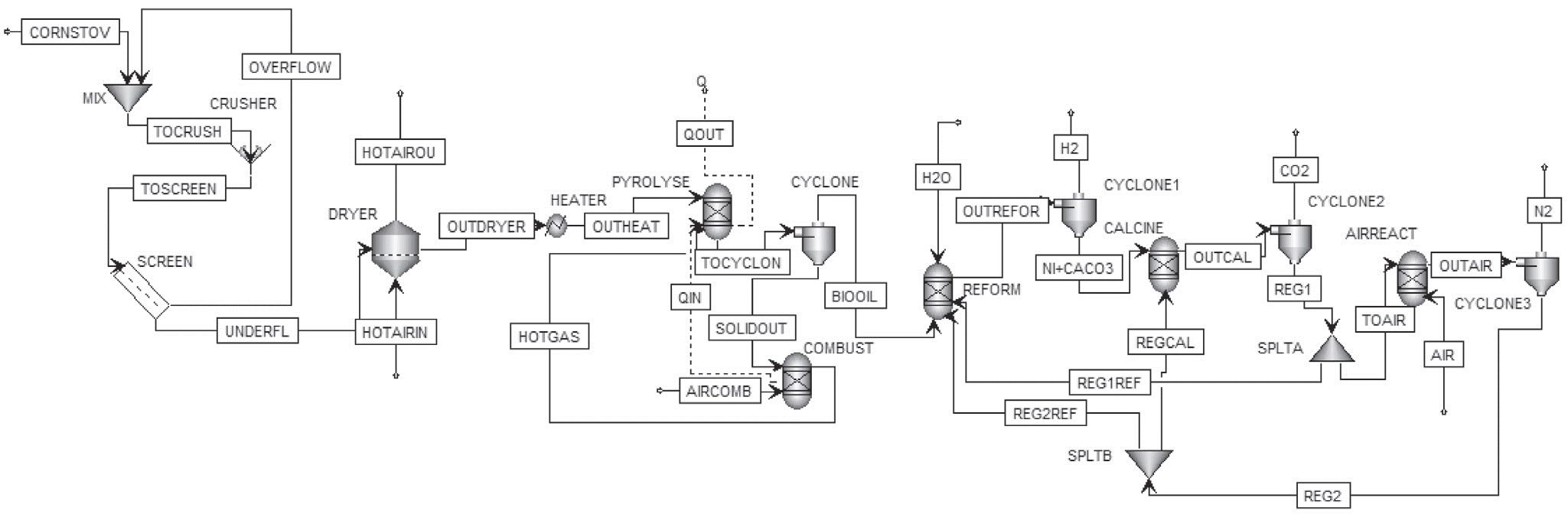

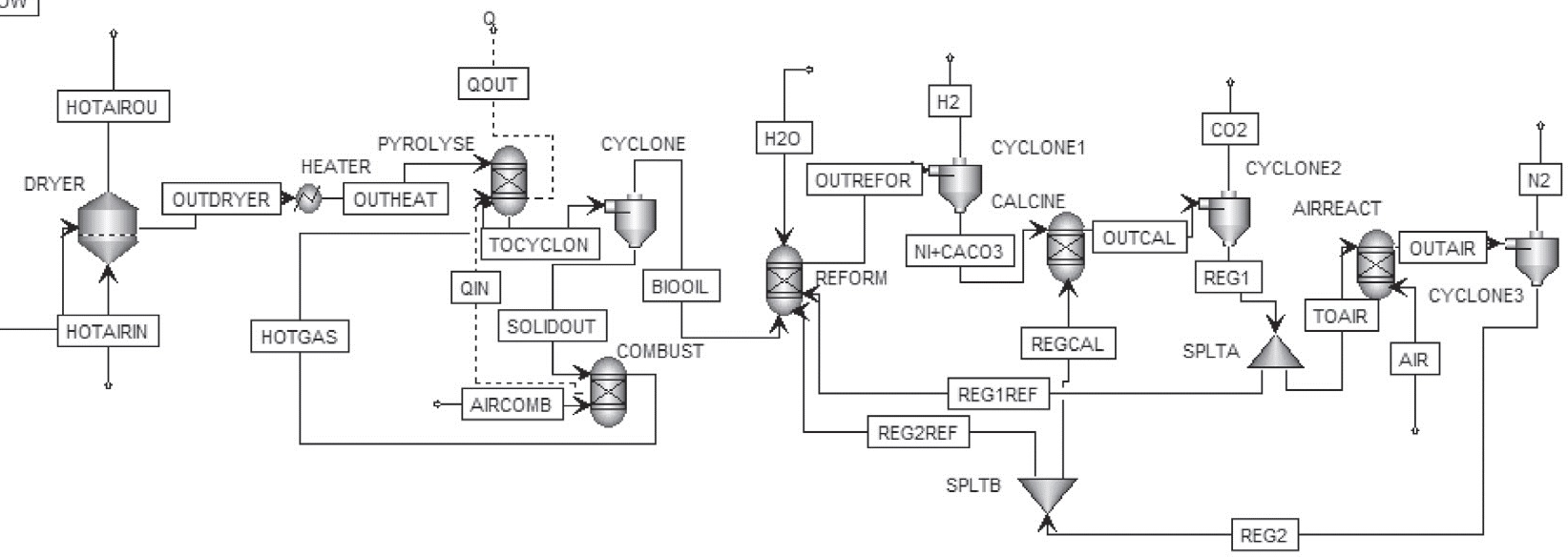

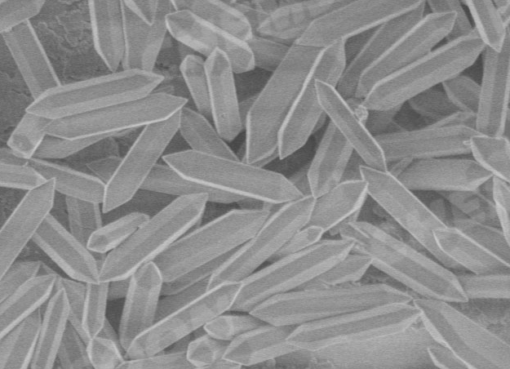

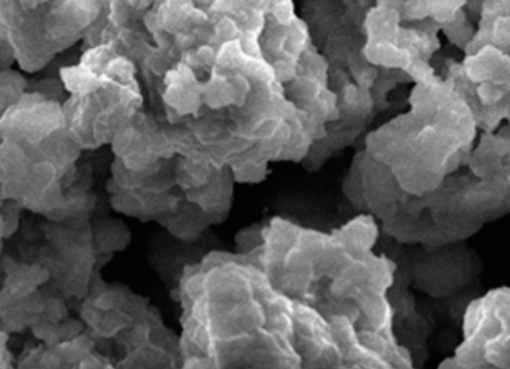

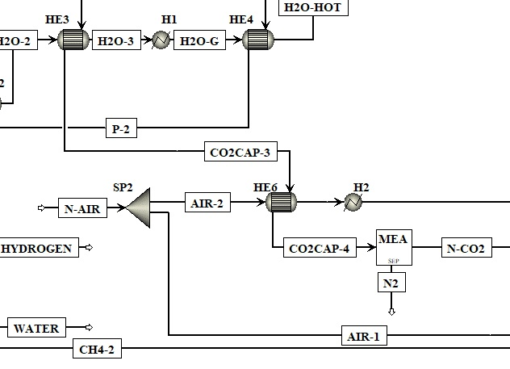

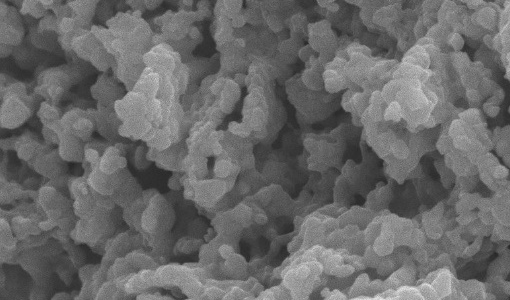

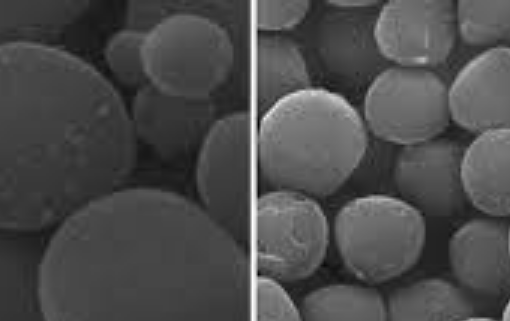

Process simulation of sorption enhanced chemical-looping reforming for hydrogen production from biomass was investigated. Corn stover was converted to bio-oil via pyrolysis prior to sorption enhanced chemical-looping reforming (SE-CLR). NiO was used as a catalyst and oxidizing agent and CaO was used as a CO2 sorbent which are cycled between the reduction and oxidation reactors. Modification of the process to incorporate a step for catalyst and sorbent regeneration was examined and compared with conventional sorption enhanced chemical-looping reforming process. By modifying the SE-CLR process with the recirculating of solids from the air reactor directly to the reformer, a maximum bio-oil conversion rate of 92%, a maximum hydrogen production yield of 153.4 g H2/kg corn stover, and a maximum hydrogen purity of 77% v/v can be obtained with a circulated NiO to bio-oil molar ratio (CNB) of 12.3; a circulated CaO to bio-oil molar ratio (CCB) of 125.2; and where the ratio of solids recovered by the air reactor from the calcination reactor (a) was set as 1, and the ratio of solids flowing directly from the air reactor to the reformer (b) was set as 0.02. The split of a fraction of solids streams to feed directly back to the reformer offers a great impact process control as operating conditions can be broadened.